Paneltech is a leading provider of bespoke furniture, joinery, modular storage, and workplace fit-outs, based in Clevedon, North Somerset. With a 40-year heritage, we have established a reputation for exceptional craftsmanship, innovative design, and a commitment to exceeding client expectations.

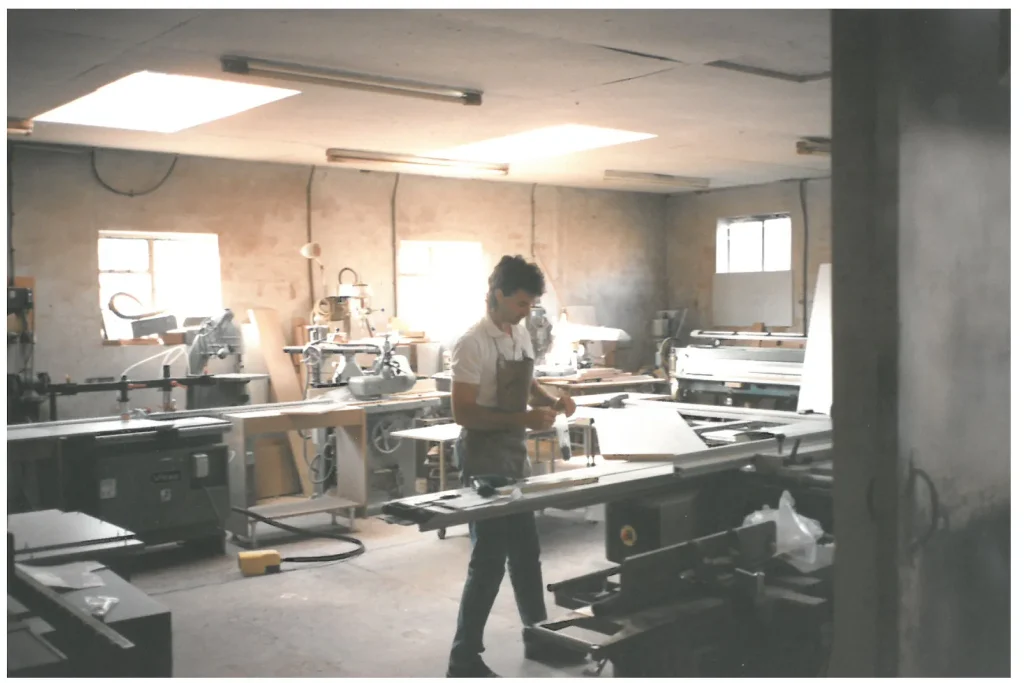

Founded in 1986, Paneltech began as a small joinery workshop, driven by a passion for creating high-quality, handcrafted pieces. Over the years, we have grown and evolved, embracing new technologies and expanding our services to meet the changing needs of our clients. While our capabilities have expanded, our dedication to traditional craftsmanship and meticulous attention to detail remains at the heart of everything we do.

What drives us at Paneltech? It comes down to a few core principles that are simply part of how we work:

Craftsmanship: We’re proud of our skilled team and the way they combine traditional techniques with modern precision to create exceptional furniture and joinery. It’s about quality, plain and simple.

Bespoke Solutions: We get that every client is different. So, we listen carefully to your needs and create designs that are a perfect fit for your style, space, and how you actually use it.

Innovation: We’re always looking for better ways to do things, whether it’s using new technology or coming up with a fresh design.

Collaboration: We believe in working closely with you throughout the whole process, from the first idea to the final installation. It should be a smooth and enjoyable experience.

Quality: We’re committed to using the best materials and maintaining the highest standards in everything we produce. No compromises.

Our People

Paneltech is more than just a company; it’s a network of dedicated individuals united by a shared vision and strong work ethic. We foster a collaborative environment with a flat hierarchy, where open communication and constructive feedback are encouraged at all levels. This approach breaks down barriers between office and factory, promoting seamless workflow and continuous improvement. We invest in our people, providing opportunities for training and development to empower them to reach their full potential. This commitment to our team has cultivated a strong bond among our experienced, highly skilled, and enthusiastic employees, who are always mindful of both the overall project goals and the contributions of their colleagues.

Our Process

Paneltech’s strength lies in our collaborative approach and the expertise of our team. Experienced designers, skilled craftspeople, and dedicated project managers work closely with you to transform your vision into reality. We believe in a transparent process, beginning with a thorough understanding of your specific needs and preferences. Our design team then develops detailed plans and drawings, incorporating your feedback at every stage.

Our Manufacturing Capabilities

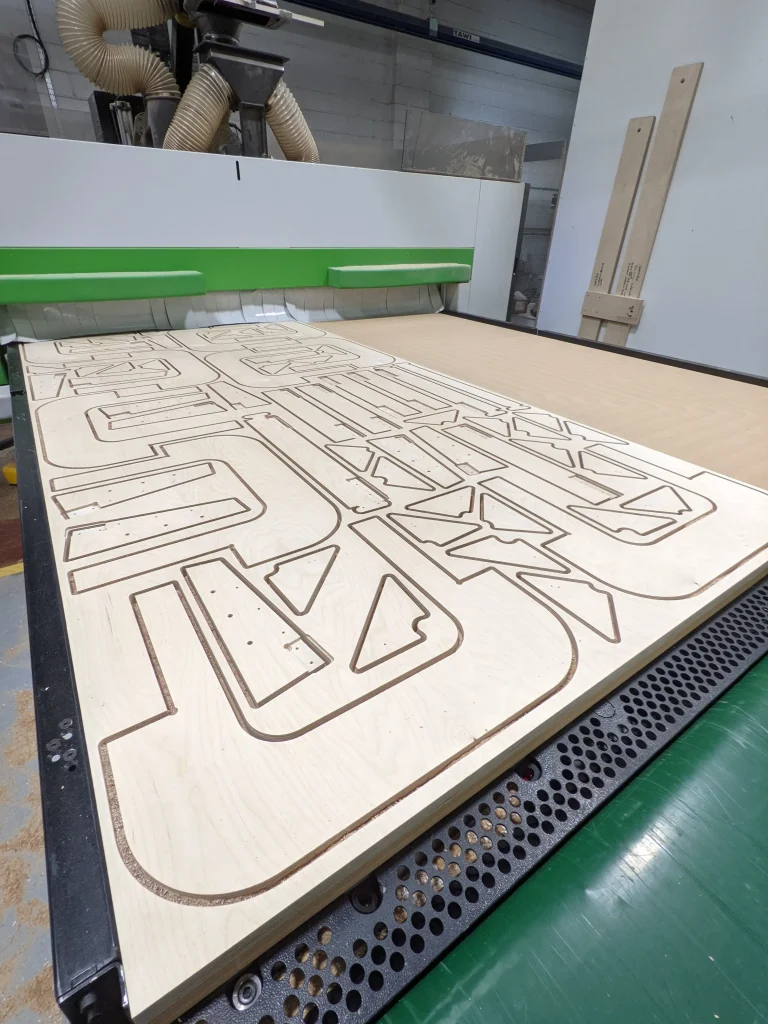

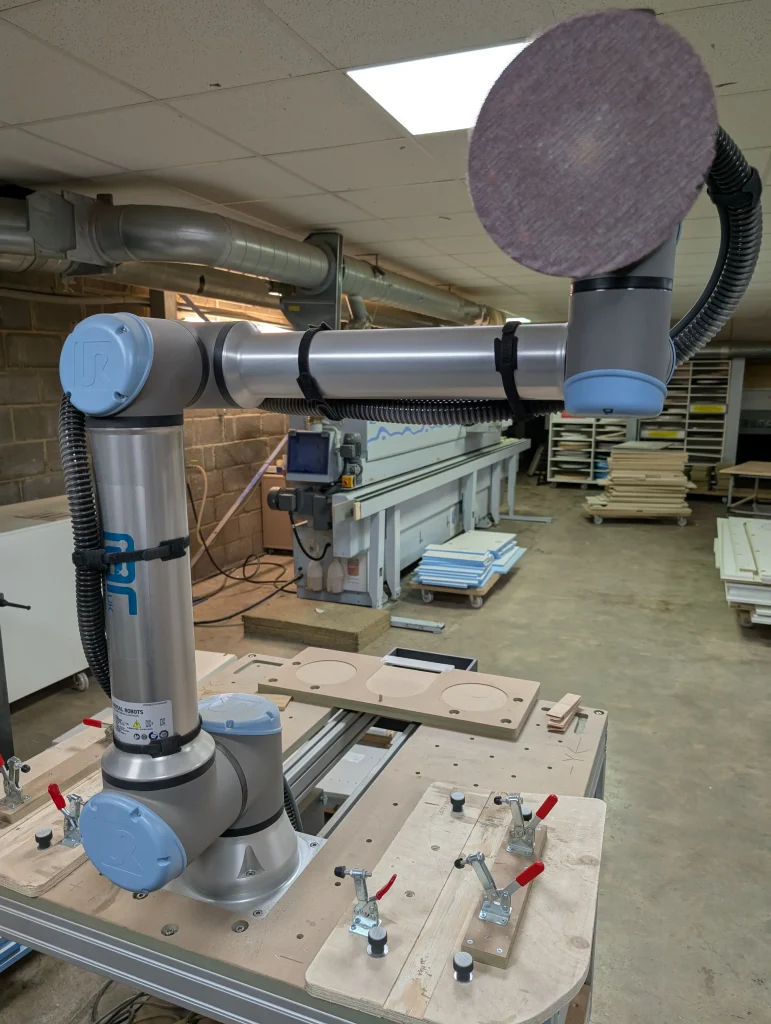

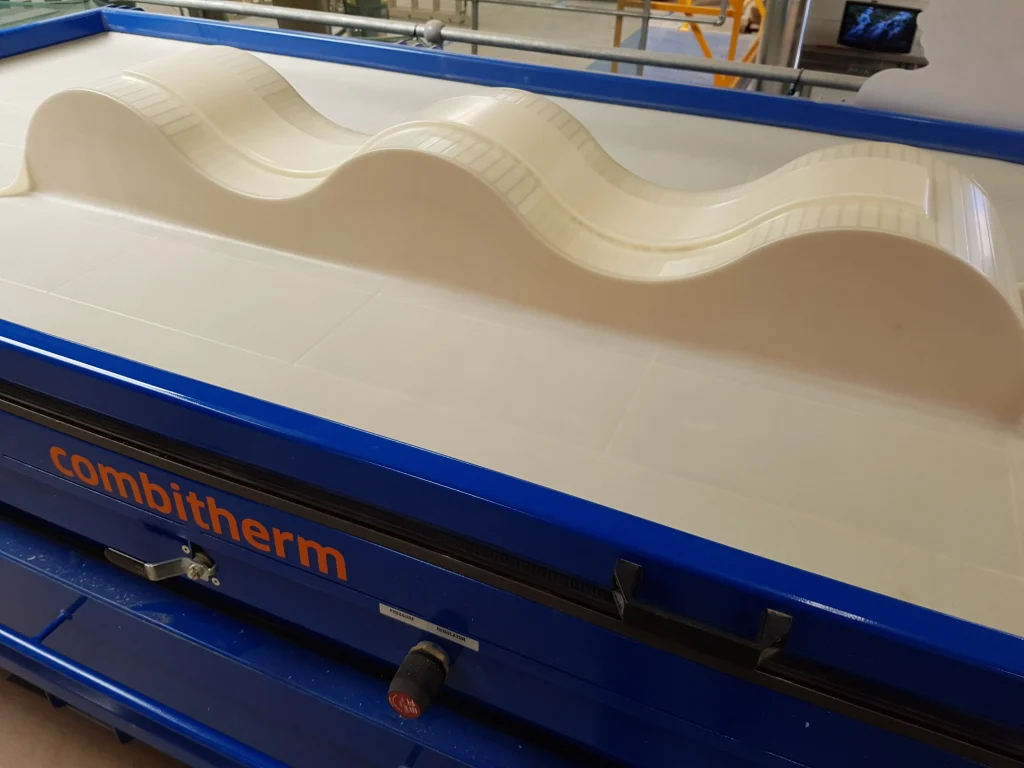

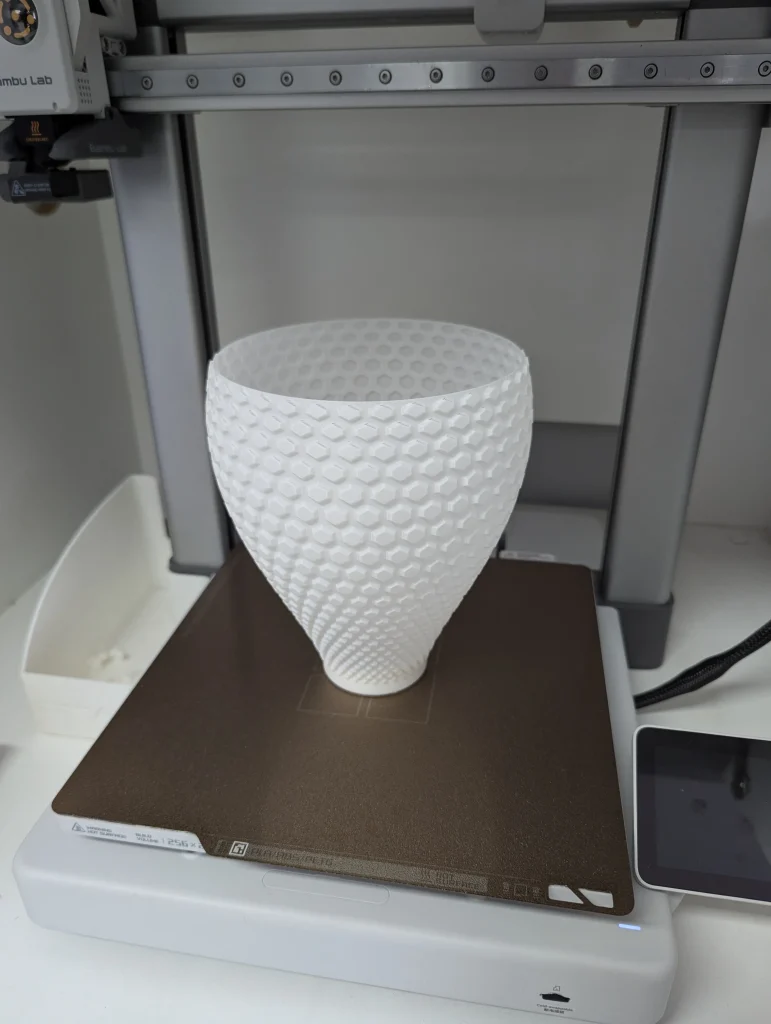

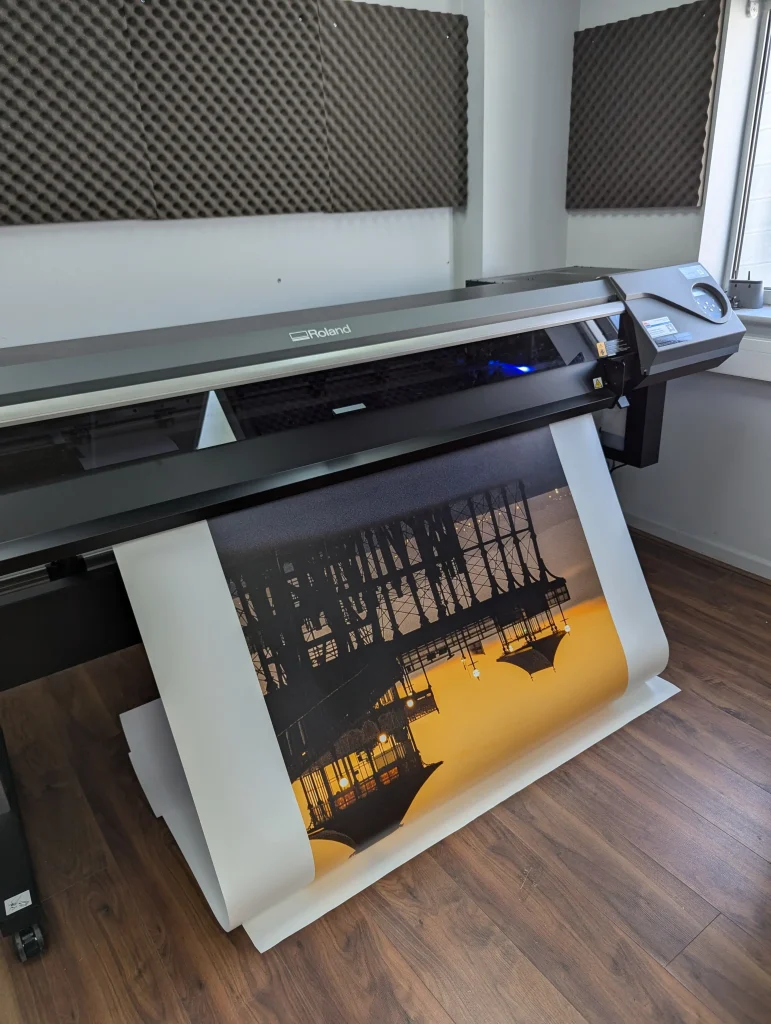

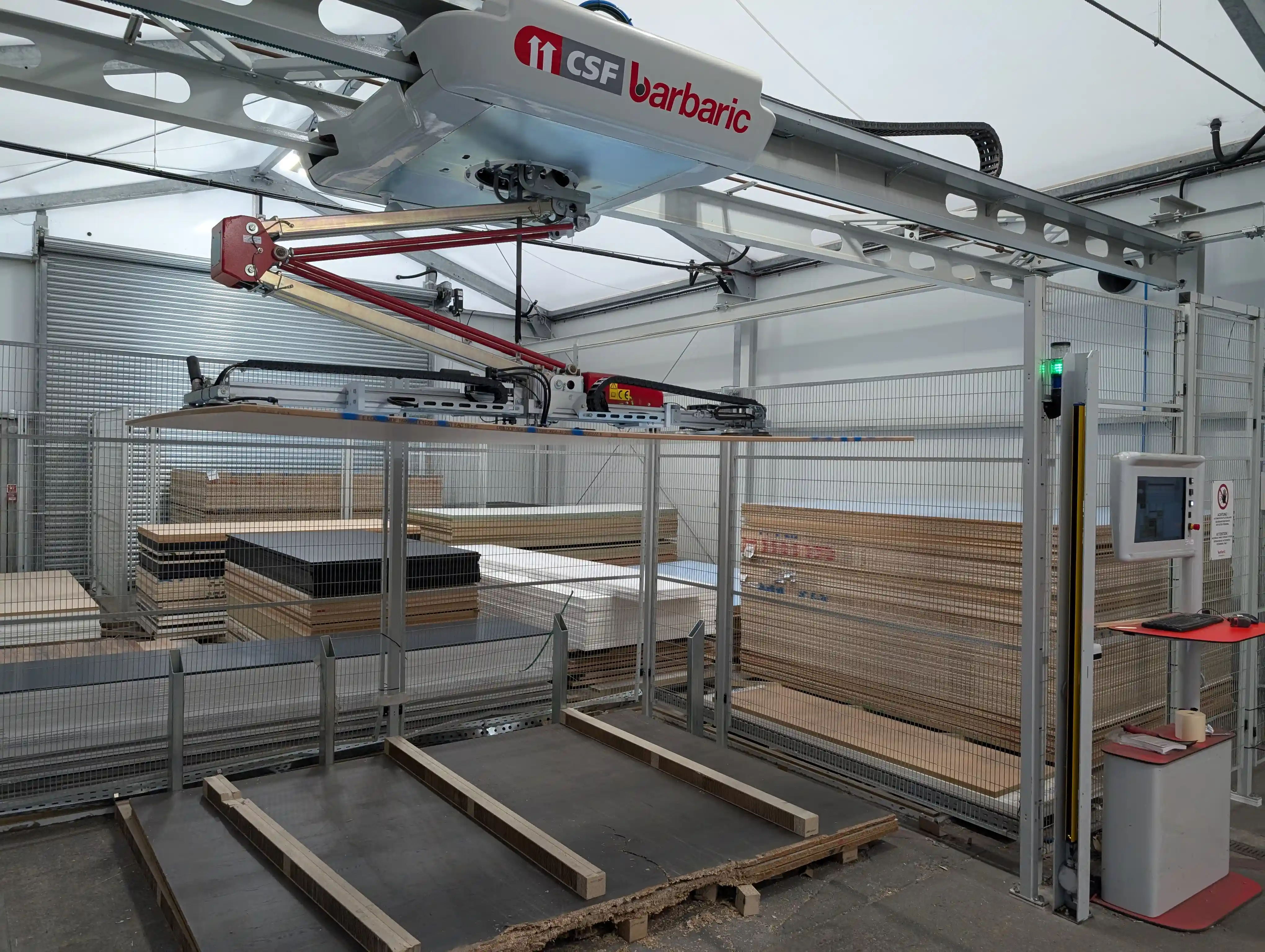

In our 15,000 square feet of purpose-designed production space, we combine traditional craftsmanship with cutting-edge technology to bring designs to life. Our advanced machinery includes automated sheet material storage, 5-axis CNCs with contour edge banding, flat bed nesting cells, robotic arms, a laser cutter, a vinyl printer, thermoforming equipment, and 3D printing capabilities, enabling us to achieve exceptional precision and efficiency. Our material expertise spans a wide range, from wood to plastics, acrylics, composites, and solid surfaces, and we partner with specialists to deliver complete projects incorporating metalwork, upholstery, glass, and more.

Our Commitment

We are passionate about creating beautiful, functional, and long-lasting spaces. Our commitment is to providing exceptional service and exceeding your expectations, whether it’s crafting a single piece of bespoke furniture or undertaking a complete workplace transformation.

Sustainability principles that benefit both our clients and the planet.

Sustainability is fundamental to Paneltech’s business philosophy. We are committed to minimising our environmental impact through a range of proactive measures, encompassing both our operations and our approach to manufacturing.

Within our production facility, we have implemented comprehensive waste reduction and recycling programmes to optimise resource use. This includes initiatives such as using biodegradable stretch wrap packaging and paper packing tape to reduce plastic waste. We prioritise the selection of responsibly sourced materials, ensuring that our supply chain aligns with our commitment to ethical and sustainable practices. To further minimise our environmental footprint, we have installed LED lighting throughout the facility with presence detection to reduce energy consumption, and we continually invest in energy-efficient equipment.

A significant part of our sustainability strategy involves generating our own clean energy. Our 100kW solar PV array provides us with substantial renewable energy, enough to power our factory, charge our growing fleet of electric vans, and even supply surplus energy back to the grid. We also actively encourage our staff to adopt sustainable commuting practices by supporting a cycle-to-work scheme and providing free electric vehicle charging at work.

We are committed to minimising waste at every stage of production. All wood waste is chipped on-site and used to heat the premises, effectively turning a byproduct into a valuable energy source. Furthermore, waste plastics from production are sent back for recycling, promoting a circular economy. We also utilise variable speed drives on our air compressor and dust extraction systems to optimise energy use and reduce unnecessary consumption.

In addition to these initiatives, Paneltech is dedicated to offsetting our carbon footprint through tree planting. We subscribe to a tree planting scheme with Ecologi (https://ecologi.com/paneltechindustriesltd), and to date, have funded the planting of over 10,000 trees. Our ongoing commitment involves planting 40 trees per month, based on planting 2 trees per month for each of our 20 employees.

We consider the full lifecycle of our products, designing for durability to minimise the need for frequent replacements. Where possible, we incorporate recyclable components, promoting a circular economy approach. By partnering with Paneltech, clients not only benefit from exceptional quality and design but also gain the assurance of working with a company that prioritises environmentally conscious manufacturing practices, helping them to achieve their own carbon reduction targets.